-

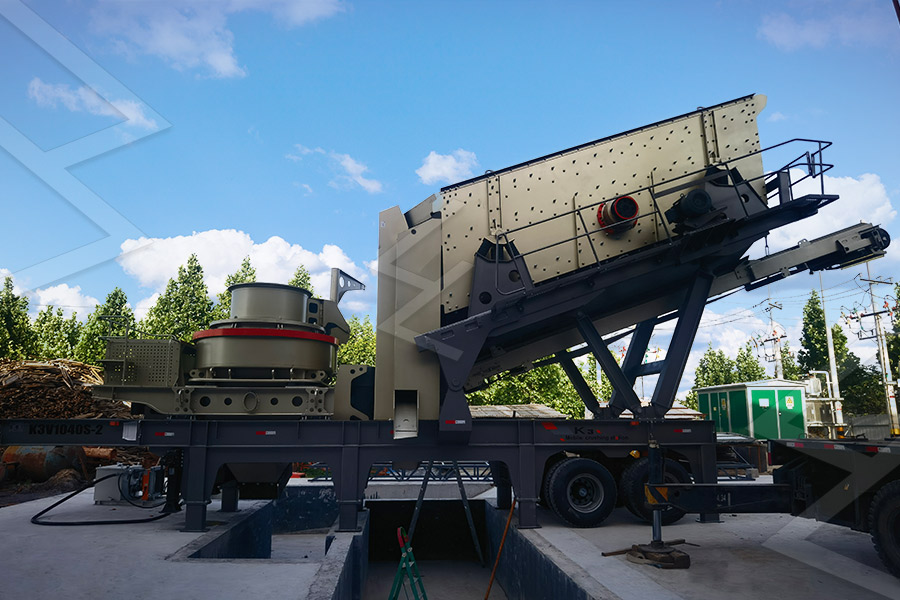

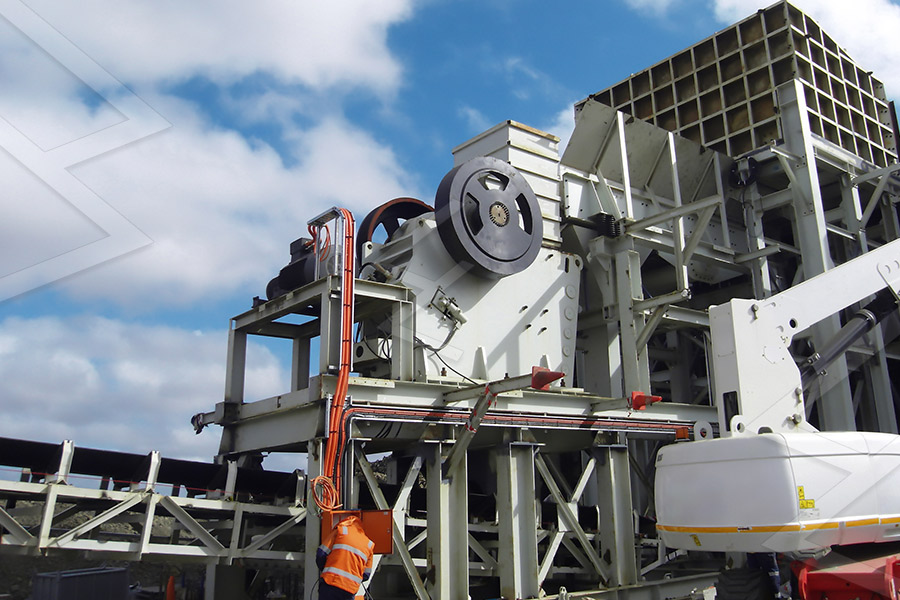

Мобильная дробилка

- дробление и измельчение меднои руды

- приспособления для шлифования коленчатого вала

- производители совокупный коробка дробилка

- каменная дробилка пасир

- мельница проект долго шаровая мельница вал

- Компания которая производит щековые дробилки в Нигерии

- обучение мобильной дробилке

- Хосуре дробилки и карьер ассоциации

- портативный рок дробилка золота в украине

- технический данные дробилки для известняка

- оборудование для измельчения мягкого угля

- дробилка каменная б у

- молотковые мельницы питермарицбург

- центробежно кольцевая мельница

- gravity separation of hematite

<шаровая мельницашаровая мельница sbm

Parameter Optimization of the Separation Process

2023year5month5day The results of the open circuit separation test that was designed on the basis of the single-factor experiment showed that the concentrate grade of Fe in the hematite–quartz mixture, with 44.12% Fe,

Read More

Gravity Separation of Zinc Mine Tailing Using Wilfley

2020year1month16day In such a way, this work aims through gravity separation to concentrate the mineral phase hematite. The Wilfley shaking table was used to process 500 g of the

Read More

A Beneficiation Study on a Low Grade Iron Ore by Gravity

2018year8month25day gravity concentration. magnetic separation. In this paper, a sample from Tange-zagh iron mine was characterized by gravity and magnetic separation methods.

Read More

Recovery of magnetite-hematite concentrate from iron

A processing flowsheet includes magnetic separation, milling and gravity concentration methods. The separation technology provides for production of iron ore concentrate with

Read More

Mineral and Technological Features of

2021year3month24day The BHQ ore was assayed as 38.9wt% Fe, 42.5wt% SiO2, and 1.0wt% Al2O3. In this ore, hematite and quartz are present as the

Read More

Processing a rare earth mineral deposit using gravity and magnetic ...

2014year7month1day Gravity separation. Gravity separation is used in mineral processing to separate minerals based on differences in specific gravity. The most common and

Read More

(PDF) Gravity Separation of Zinc Mine Tailing Using Wilfley

2020year1month1day In such a way, this work aims through Gravity separation to concentrate the mineral phase Hematite. The Wilfley shaking table was used to process 500 g of the

Read More

Gravity separation by falcon concentrator- an over review

Enhanced gravity separation (EGS) is a physical separation technique that employs centrifugation to separate fine valuable minerals from their gangue phases based on their

Read More

Influence of process parameters of dry high intensity

2017year3month10day Standard physicochemical methods such as froth flotation and gravity separation (spiral concentrator, jigging, heavy media separation) used to separate the

Read More

SPECIAL IRON ORE PROCESSING ISSUE Development of

2018year10month22day Key words: Low-grade iron ore fines, Mineralogy, Gravity separation, Size reduction, Magnetic separation, Iron/ iron ores. Introduction martite and magnetite, in

Read More

Gravity Separation - ScienceDirect

2016year1month1day Gravity Separation Performance. The evaluation of the separation method or performance of a gravity separation device is usually based on a sink-float analysis and washability curves. A great many applications of the washability curves are applied to cleaning operations in the coal preparation field (coal washing) so that most reference is

Read More

Design of beneficiation scheme of Banded Hematite Jasper

2021year1month1day Gravity separation is relatively easy when the quotient is greater than 2.5. As the value of the quotient decreases, the efficiency of separation decreases. Below about 1.25, gravity separation is not practically feasible. The specific gravity of hematite is 5.5 to 6.5 whereas it is 4.1 to 4.3 for goethite. Specific gravity of quartz is 2.6.

Read More

Gravity Separation of Zinc Mine Tailing Using Wilfley

2023year8month23day Gravity Separation of Zinc Mine Tailing Using Wilfley 349 residue is composed of Fe 7%, Mg 10.4%, Ca 19%, Si 1.75%, and Zn 1.7%, pre-viously characterized by inductively coupled plasma ...

Read More

3 Types of Jig Machine You Need to Know - Mining-pedia

2020year11month6day Diaphragm jig is a type of jigging machine that is widely used in gravity separation plants, whose working principle is to drive the diaphragm by eccentric connecting rod, cam lever or hydraulic device causing reciprocating motion.Based on the diaphragm installation position, diaphragm jigs can be divided into top-moving (side-moving)

Read More

Processing a rare earth mineral deposit using gravity and

2014year7month1day Rare earth (RE) mineral deposits are typically processed using several different unit operations including flotation, gravity, magnetic and electrostatic separation techniques. Two of the most important beneficiation techniques for RE minerals are gravity and magnetic separation. Many RE minerals are found alongside low specific gravity

Read More

Recovery of magnetite-hematite concentrate from iron

separation in low intensity field for magnetite recovery and gravity concentration for hematite recovery. 3 Results and discussion As it was shown above, the tailings contain about 5% of coarse particles with diameter more than 1 mm. Due to low iron content and big amount of unliberated magnetite and hematite in this fraction, initial tailings

Read More

Rare Earth Beneficiation and Hydrometallurgical Processing

2016year2month11day The commonly used ore beneficiation technologies include gravity separation, flotation, and magnetic separation. 2.1.1 Gravity Separation. The successful application of gravity separation depends on the difference of specific gravity between the rare earth minerals and the major gangue materials. The particle size is also very

Read More

Mineral and Technological Features of Magnetite–Hematite

2021year3month24day Analysis of the current technical solutions for the processing of iron ores showed that the high-grade ores are directly exposed to metallurgical processing; by comparison, low-grade ores, depending on the mineralogical and material composition, are directed to beneficiation including gravitational, magnetic, and flotation processes or their

Read More

Hematite - an overview ScienceDirect Topics

Hematite possesses the corundum structure (α-Fe 2 O 3) shown in Fig. 4.2, specifically trigonal-hexagonal scalenohedral, class 3 2/m, and space group R-3c (a ... In most cases, the fines product requires additional separation/desliming stages to remove fines containing a high level of clay and other waste minerals.

Read More

(PDF) Gravity separation by falcon concentrator- an over

2022year1month20day Gravity separation by falcon concentrator- an over review. January 2022; Separation Science and Technology; ... Hematite. Quartz, Kaolinite, Smectite. −74 -25 80 G (fixed) 20–60 (bar)

Read More

Mineralogy and textural impact on beneficiation of goethitic

2017year5month1day The effect of mineralogy and texture on the beneficiation of goethitic ores from two different origins is highlighted. Sample A having 54.47% Fe with 8.57% loss of ignition (LOI) indicates the presence of vitreous and ochreous , martite and microplaty hematite + 100 μm size class are 74% for Sample A and 37% only for Sample B which

Read More

Table 1 Volumetric magnetic susceptibilities of iron minerals

Hematite and goethite are converted into magnetite by roasting, allowing separation by low intensity magnetic equipments. Shao, Veasey and Rowson (1996) measured magnetic susceptibility of iron ...

Read More

(PDF) Gravity Separation of Zinc Mine Tailing Using Wilfley

2020year1month1day The Wilfley shaking table was used to process 500 g of the tailing. Three different materials were obtained after the Separation process: Hematite concentrate, middling, and Gravity separation ...

Read More

Molecular models of hematite, goethite, kaolinite, and

2022year10month5day Although hematite presents almost the same ASC values as kaolinite, the iron-terminated surfaces of hematite are coordinated by water. ... Flotation behavior and mechanism of styrene phosphonic acid as collector on the flotation separation of fluorite from calcite. J. Mol. Liq., 326 (2021), Article 115261, 10.1016/j.molliq.2020.115261.

Read More

Separation, upgrading, and mineralogy of placer magnetite

2017year7month10day The black sand magnetite is a raw material to produce iron and steel. High content magnetite in the top meter beach sands of the north-west of El-Burullus Lake of Egypt is separated and mineralogically and geochemically investigated. Magnetite content obtained by laboratory techniques varies between 2.92 and 0.11 wt%, with 1.15 wt%

Read More

A review on the characterisation and processing of oolitic iron ores ...

2018year9month1day A similar processing flow sheet was described by Zhao (2008) for processing oolitic hematite ore associated with the Longyan Iron Mine of Xuan Steel in Hebei province in China. The ore contained 47.66% total Fe and was ground to 65% passing 74 µm ahead of gravity separation.

Read More

Physical separation of iron ore: magnetic separation

2022year1month1day It is therefore easier to upgrade specularite using magnetic separation, compared with hematite. In contrast, limonite is the least susceptible to magnetic fields and therefore most difficult to recover using magnetic separation. ... Gravity separation also has the advantage of low operating costs, but it is often implemented at a much smaller ...

Read More

Wet High Intensity Magnetic Separation of Iron Minerals

1996year1month1day It was found that hematite—1 was a strongly paramagnetic mineral, and the effect of particle size in WHIMS was not significant. ... Of interest is the magnetic separation, gravity concentration ...

Read More

Investigating the performance of a novel polyamine

2020year4month15day Traditional gravity separation and magnetic separation technology cannot meet the need of obtaining high-quality useful minerals, especially in the separation of iron ore [6], [7], [8]. ... PDDA could be used as a potential collector in the flotation separation of quartz and hematite. Synthesis of samarium orthoferrite-based perovskite ...

Read More

Terminal Velocity - an overview ScienceDirect Topics

MarsSedEx I: Instrument Development. Nikolaus Kuhn, in Experiments in Reduced Gravity, 2015. 6.2 One-Chamber Settling Tube (OCST) experiment. The experiment aimed at testing the feasibility of terminal velocity measurements under reduced gravity. If successful, future tests could be designed to measure a range of particle settling velocities on Mars, to

Read More