-

Мобильная дробилка

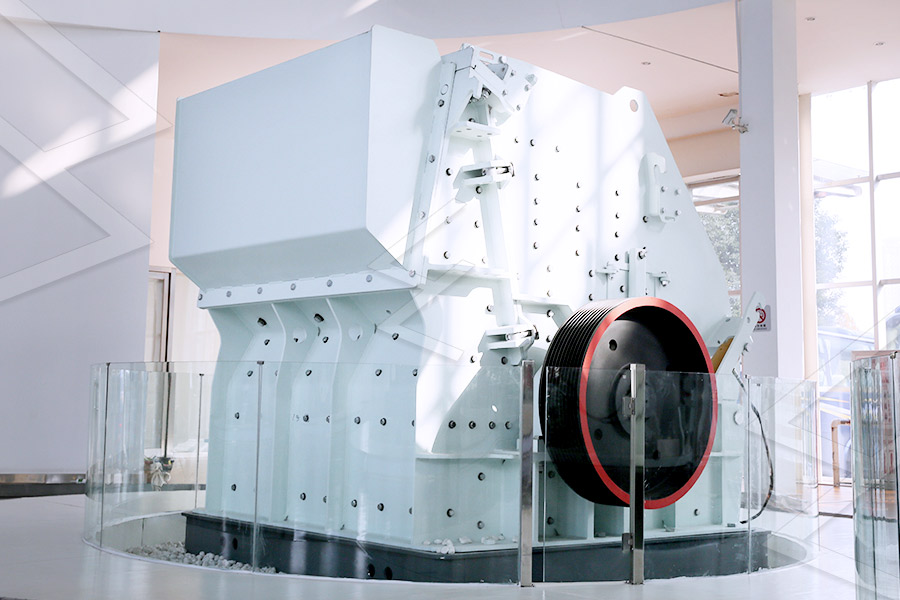

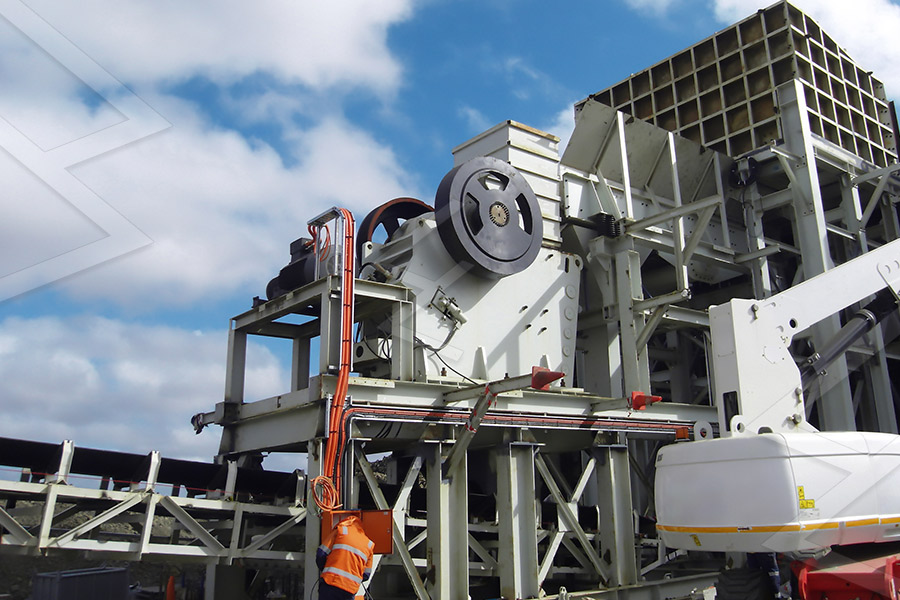

- Изображения камень дробилки машины

- гусеничный передвижной щебеночный завод

- аренда дробилки гравия до н.э.

- схема шахтного котла

- украина продам б у угольную мельницу

- небольшой медный шлак дробилка

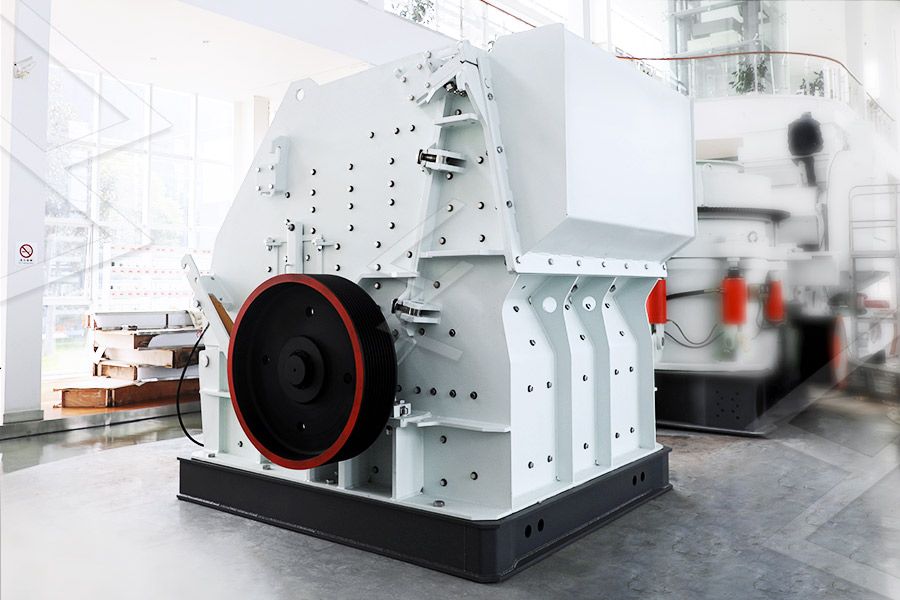

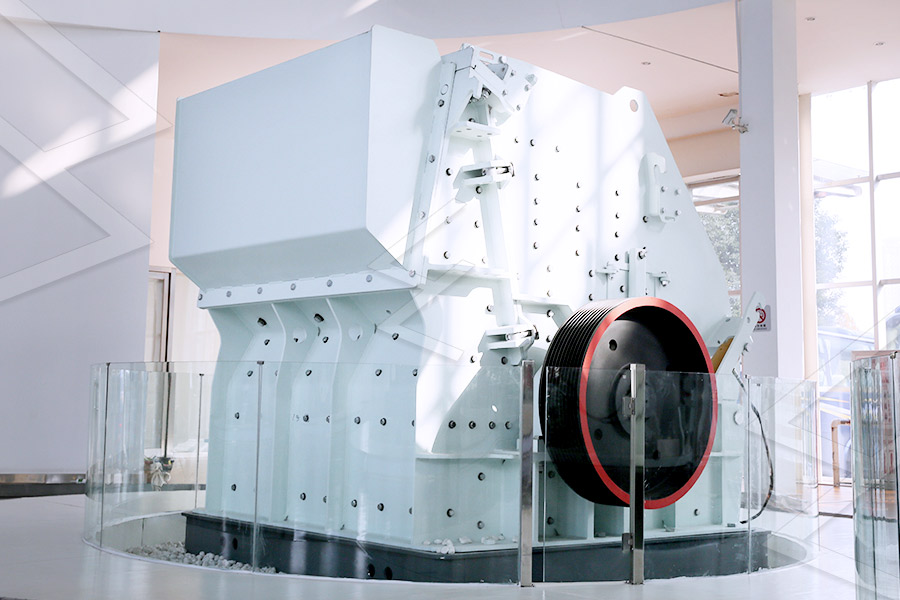

- ударная дробилка базальт

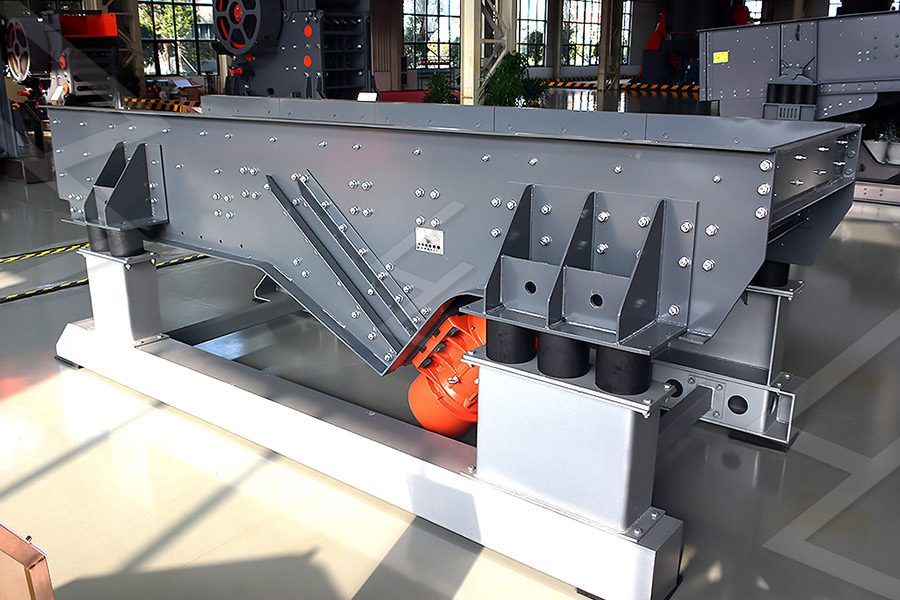

- камнедробильные заводы и мельницы

- щековая дробилка расчеты

- устроиство мельници для измельчения тирси

- золото из песка поиск

- 50mt цементная мельница

- ізмельчитель пун 5 до комбайна нива

- горнодобывающие компании в ньюкасле

- magnetic separation is used for the concentration of

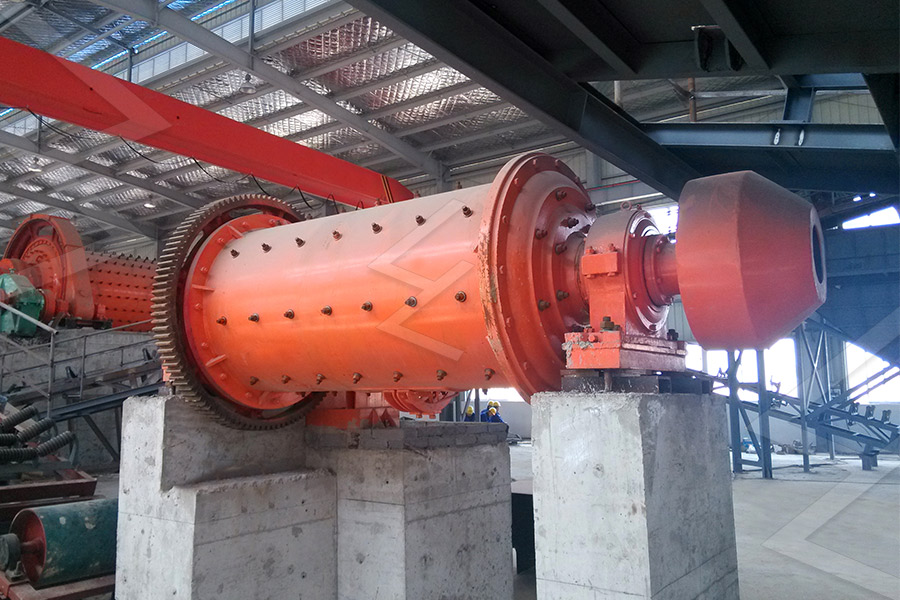

<шаровая мельницашаровая мельница sbm

Magnetic Techniques for Mineral Processing - ScienceDirect

2015year1month1day In the field of mineral processing, magnetic separation is mainly used for concentration of magnetic components and for removal of magnetic impurities, under dry

Read More

Magnetic Separation SpringerLink

Abstract. Magnetic separation utilizes the force of a magnetic field to produce differential movement of mineral particles through a magnetic field; this and the fundamental

Read More

Intensity Magnetic Separator - an overview - ScienceDirect

Typical uses: Separation of ferro- and paramagnetic materials such as minerals and ceramics. FDS process ratings: 3 C, 2, 4, 8 (LIMS or HIMS); 1 S, 2, 4, 8 (HGMS). Typical

Read More

6 Magnetic Separation - Springer

2017year8month25day separators are usually the last stage of magnetic separation to make a final magnetic concentrate and a nonmagnetic tailing. Dry Magnetic Separators (i) Magnetic

Read More

Magnetic Separation SpringerLink

2022year2month28day Magnetic Separation. Saeed Chehreh Chelgani Ali Asimi Neisiani. Chapter. First Online: 28 February 2022. 427 Accesses. Abstract. The differences in

Read More

Magnetic separation: its application in mining,

2017year7month21day The use of strong magnetic field gradients and high magnetic fields generated by permanent magnets or superconducting coils has found applications in many fields such as mining, solid state

Read More

Magnetic Concentrate - an overview ScienceDirect Topics

Column magnetic separator is developed on the principle of magnetic agglomeration of strongly magnetic minerals such as magnetite in a low-intensity magnetic field, and is

Read More

MAGNETIC AND ELECTRICAL SEPARATION - Springer

2017year8month25day Mineral Processing-Magnetic and Electrical Separation 573 When the maximum magnetisation has been achieved a particle is saturated (at). In magnetic

Read More

High-Efficiency Extraction of Fe, V, and Ti from Vanadium

2022year2month1day A method has been proposed for treatment with VTMC consisting of carbothermal reduction, magnetic separation, and firing with alkali metals followed by

Read More

Magnetic Separation:

2023year10month26day 5 Examples of Magnetic Separation: Magnetic drum separator: A drum-shaped magnet that separates ferrous material from non-magnetic material. It is commonly used in recycling, mining, and the steel

Read More

Mineral processing - Concentration, Separation, Flotation

Mineral processing - Concentration, Separation, Flotation: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill. In large-scale operations this is accomplished by taking advantage of the different properties of the minerals to be separated. These properties can be colour (optical sorting), density

Read More

Unified View of Magnetic Nanoparticle Separation

The migration process of magnetic nanoparticles and colloids in solution under the influence of magnetic field gradients, which is also known as magnetophoresis, is an essential step in the separation technology used

Read More

Quantitative characterization and magnetic separation of

2023year6month25day Magnetic separation. In this experiment, 50 g of the original tailings (TM0) were mixed with distilled water. After stirring for 30 min at 200 rpm using an Electric stirrer (OS-400 PRO), a magnetic bar was used to separate the magnetic and non-magnetic products during the one-step magnetic separation process.

Read More

Minerals Free Full-Text Mathematical Model of Ilmenite Separation ...

2022year6month29day High gradient magnetic separation is widely used in magnetic minerals upgrading, and its separation performance is significant depending on the parameters. In this investigation, the Mathematical model of the plate high gradient magnetic separator is established, the magnetic induction and the flow field distribution are investigated based

Read More

Versatile magnetic configuration for the control and ... - Nature

2023year3month31day For example, for a 500 µm wide capillary and magnet separation of 3 mm even a 100 μm displacement of the capillary to the left (Fig. 3b) is sufficient to break the CSC, while for magnet ...

Read More

CBSE Class 12 : Different methods of concentration of ores

2023year10month27day Concentration, dressing, or beneficiation of ores is the process of removing undesirable particles from ore. There are various steps to it. The variations in physical characteristics of the existing metal complex and that of the gangue are used to separate the needed material from the ore. Gangue is a mineral that contains

Read More

Processing a rare earth mineral deposit using gravity and magnetic ...

2014year7month1day 3.2. WHIMS results. The Nechalacho ore was processed using a combination of WHIMS and gravity pre-concentration using either a Knelson (80% – 53 μm feed) or a Falcon (80% – 44 μm feed) Concentrator to exploit the differences in specific gravity and magnetic properties of the different minerals in order to achieve separation.

Read More

Immunomagnetic separation: An effective pretreatment

2020year10month18day Immunomagnetic separation: An effective pretreatment technology for isolation and enrichment in food microorganisms detection ... First, the basic principle of IMS in the concentration of food bacteria is presented. Second, the effect of different factors, including the sizes of magnetic particles (MPs), immobilization of antibody and operation ...

Read More

Minerals Free Full-Text Dry Permanent Magnetic

2022year9month9day Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency. These tools not only discard some amount of bulk gangue from the raw ore, thereby reducing the volume of the grinding operation and cutting energy consumption, but also

Read More

Methods of concentration of Ores – Gravity Separation.

2023year10month27day Gravity separation or hydraulic washing. The gravity separation method, also known as hydraulic washing, is used for metals that are heavier than the gangue particles. In this method, water is used to enrich the ore. The ore is passed through a stream that goes upward, pushing up all the lighter particles mainly comprising impurities, while

Read More

Q. Magnetic separation is used for increasing concentration

Solution: Hematite (F e2O3) Iron ores are concentrated by this method. Magnetic separation is used for increasing concentration of the following (A) Horn silver (B) Calcite (C) Hematite (D) Magnesite. Check Answer and Sol.

Read More

A Review of Secondary Aluminum Production and Its Byproducts

2021year7month30day A preheating method is mainly used for household waste, such as cans, to remove plastic coatings or organic paints before the remelting process. The type of sorting technique implemented to remove the residue depends upon the residue type. The following are the four main separation techniques widely used in SAP. Magnetic Separation

Read More

Minerals Free Full-Text A Novel Pneumatic Planar Magnetic

2020year8month27day In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore. In the present study, we have extended the studies on the PMS with the focus on investigating how various PMS processing flowsheet configurations influence its

Read More

Magnetic and Electrostatic Separation - ScienceDirect

2016year1month1day Magnetic, electrostatic, and electrophoresis methods of mineral separations, singly or in combination, have been used successfully as tools in the separation and concentration processes of minerals. In this chapter, we have tried to describe and explain some of the relevant principles underlying the existence of such properties in minerals

Read More

Flotation-magnetic separation for the beneficiation of rare

2018year4month1day Flotation-magnetic (FM) separation is a newly-developed technology for the economic recovery of rare earth elements from the Dalucao ore. The FM process selectively agglomerates the rare earth particles while separating them from gangue minerals by bubble flotation. The agglomeration of fine bastnaesite particles has been observed by optical ...

Read More

Separation and measurement of silver nanoparticles and

2014year2month15day The advantage of this method over commonly used separation techniques is its ease of separation by the use of an external magnetic field. Experiments with spiked environmental samples revealed that AgNPs can be recovered in complex matrices; hence, this method has the potential as an analytical tool for concentrating and detecting

Read More

High-gradient magnetic separation using ferromagnetic membrane

2016year1month1day Magnetic separation is a commonly used technique in metallurgy, coal industry, for wastewater treatment, etc., to extract and concentrate strongly magnetized particles from a powder or a suspension. ... The concentration of magnetic phase in suspension before and after separation was determined by electron magnetic resonance

Read More

Gravity Concentration - an overview ScienceDirect Topics

Mineral concentration is a method to separate valuable minerals based on differences in properties of the particles from milled mineral mixtures. Mineral concentration technologies include gravity concentration, magnetic concentration and flotation. These technologies are also used in the separation of plastic waste (Alter, 2005; Fraunholcz 2004).

Read More

VII. MAGNETIC SEPARATION - CORE

2020year5month6day VII. MAGNETIC SEPARATION This is one ofthe concentration processes that utilize the differences in magnetic properties of various minerals present in the ore body. The magnetic fraction may be valuable or gangue depending upon its use in a particular flow sheet or process and so also the non-magnetic fraction, e.g., separation of

Read More